The Role of Polyester Composite Straps in Wood Transportation

In the realm of logistics and transportation, the safe and efficient handling of goods is paramount, especially when it comes to the transport of delicate and valuable items such as wood. Wood, being a natural resource, requires special attention to prevent damage during transit, which can lead to significant financial losses and environmental impact. Polyester composite straps have emerged as a revolutionary solution in this context, offering a blend of strength, durability, and flexibility that is unparalleled by traditional materials.

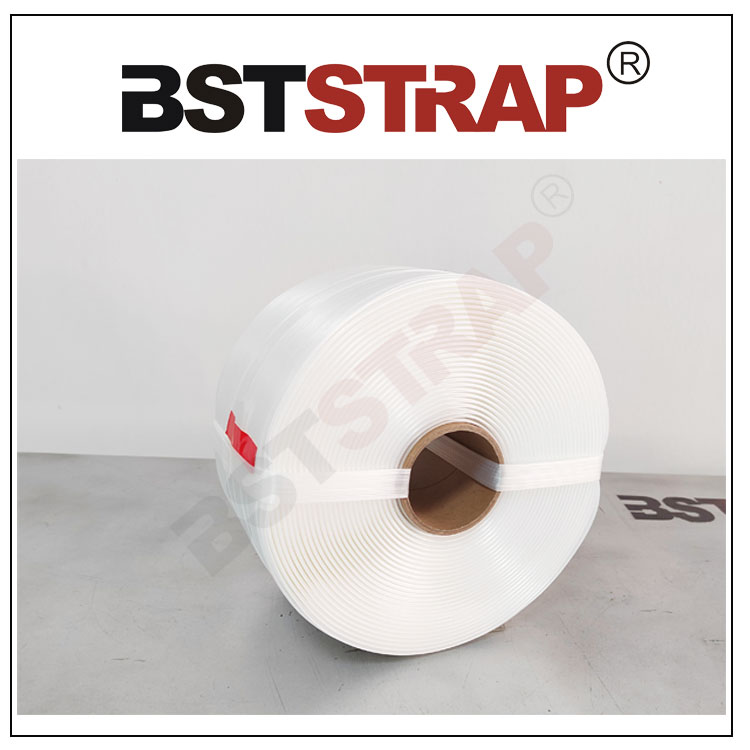

Polyester composite straps, often referred to as PET straps, are engineered from high-density polyethylene terephthalate (PET) fibers. These straps are known for their high tensile strength, which is essential for securing loads during transportation. The strength-to-weight ratio of polyester composite straps is superior to that of steel, making them an ideal choice for heavy-duty applications such as wood transportation.

One of the primary advantages of using polyester composite straps in wood transportation is their ability to evenly distribute the load's weight across the entire surface of the wood. This uniform distribution minimizes the risk of warping, cracking, or splitting, which are common issues with traditional metal straps or ropes that can concentrate pressure on specific points. The non-abrasive nature of polyester straps also prevents damage to the wood's surface, maintaining its quality and appearance upon arrival.

In addition to their strength and protective qualities, polyester composite straps are also highly resistant to environmental factors. They are not susceptible to rust or corrosion, unlike steel straps, which can degrade over time and pose a risk to the wood they are securing. This resistance to moisture and chemicals ensures that the straps remain reliable even in humid or corrosive environments, which are often encountered during the transportation of wood.

The lightweight nature of polyester composite straps is another significant benefit, particularly when considering the fuel efficiency of transportation vehicles. Lighter straps mean less overall weight for the vehicle to carry, leading to reduced fuel consumption and lower carbon emissions. This not only contributes to a greener supply chain but also translates to cost savings for logistics companies.

Furthermore, polyester composite straps are easy to handle and apply, thanks to their smooth surface and flexibility. This ease of use can lead to increased efficiency in loading and unloading processes, as well as reduced risk of injury to workers. The straps can be easily adjusted to fit various sizes and shapes of wood, ensuring a secure and customized fit for each load.

In terms of sustainability, polyester composite straps are a more environmentally friendly option compared to steel. They can be recycled at the end of their service life, reducing the environmental footprint of the transportation industry. This aligns with the growing global emphasis on sustainable practices and the circular economy.

In conclusion, polyester composite straps have become an indispensable tool in the wood transportation industry. Their combination of strength, durability, and environmental friendliness makes them an ideal choice for securing wood loads during transit. As the demand for sustainable and efficient logistics solutions continues to grow, the adoption of polyester composite straps is expected to increase, further enhancing the safety and reliability of wood transportation processes.